Introduction

The advent of HP Jet Fusion technology in the domain of digital manufacturing has opened a new horizon for designing interlocking parts. This cutting-edge technology allows the fabrication of complex assemblies like chains in a single print run, a feat unachievable by traditional manufacturing methods. This blog post delves into the intricacies and creative possibilities of designing interlocking parts using HP Jet Fusion.

The Basics of Designing Chains:

Chains, composed of interlocked links, epitomize the concept of interconnected parts. In powder-based 3D printing, such as HP Jet Fusion, these chains can be produced in a single printing process, provided they are meticulously designed with adequate gaps. This capability eliminates the need for post-printing assembly, streamlining the manufacturing process.

- Design Considerations: The key to successfully printing interlocking chains lies in ensuring sufficient gaps between the links. This prevents accidental fusing during the printing process, maintaining the chain’s mobility and functionality.

- Example Designs: Basic link designs serve as an excellent starting point for exploring the potential of chain printing. These can range from simple, traditional link shapes to more complex and customized forms.

Innovations in Chain Printing:

HP Jet Fusion technology not only simplifies the production of standard chains but also opens the door to innovative design possibilities.

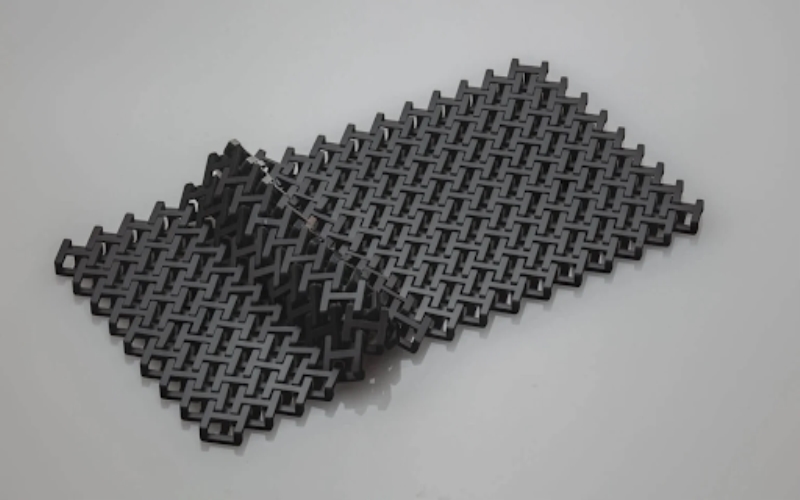

- Folded Chains for Compact Packing: One remarkable innovation is the design of chains that are folded for compact packing. This approach is particularly advantageous for printing parts that exceed the dimensions of the print bed. By designing chains that can be folded, manufacturers can create longer assemblies without being constrained by the printer’s size.

- Customized Chain Designs: Beyond traditional link designs, HP Jet Fusion allows for the creation of chains with unique geometries, textures, or even reconfigurable links. Designers can experiment with various shapes and forms, pushing the boundaries of what’s traditionally been possible with chain design.

Applications and Implications:

The ability to print interlocking parts like chains has significant implications across various industries. From intricate jewelry designs to functional mechanical assemblies, the range of applications is vast. In sectors such as automotive, aerospace, and industrial machinery, the ability to print complex chain assemblies in one go dramatically reduces production time and costs. Additionally, in the realm of fashion and art, designers can leverage this technology to create unique, intricate pieces that were previously unfeasible.

Conclusion

HP Jet Fusion’s capability to print interlocking parts such as chains marks a significant advancement in the field of digital manufacturing. This technology not only simplifies production processes but also encourages innovation in design, allowing for the creation of complex, functional, and aesthetically pleasing parts. As digital manufacturing continues to evolve, HP Jet Fusion stands as a testament to the limitless possibilities of 3D printing technology.